Understanding Crane Service Classifications

Ago 13, 2025

Understanding crane service classifications, including EOT crane classification, is essential for selecting and installing a crane appropriate for your application and facility. Choosing the appropriate solution will help ensure the working conditions and longevity of your overhead system. Pushing your system beyond its service rating is both dangerous and counterproductive.

Using an overhead crane in accordance with its service classification will protect your long-term investment, support worker safety, and provide valuable insight about the maintenance and inspection requirements of your overhead system.

What Are Crane Service Classifications?

Crane service classifications are a standardized way of determining how much work a crane is designed to handle over its lifetime. These classifications help warehouse managers and operations teams select the right crane based on the operating environment, usage frequency, and load weight.

Multiple standards exist to rate the service class of a crane and hoist, including those developed by the Crane Manufacturers Association of America (CMAA). CMAA crane classifications are established based on a crane’s average load intensity and number of lift cycles — in other words, how much weight the system will need to lift, how high the materials will need to be lifted, and the frequency within an hour that the crane will need to perform those tasks.

Why Do Crane Classifications Matter?

Two cranes may look identical in size and capacity, but their internal components could be rated for different duty cycles. Choosing the right CMAA crane classification ensures:

- The crane is built to withstand typical load intensity and lift cycles.

- Maintenance needs align with actual usage.

- Components such as motors, brakes, and hoists are correctly rated for the right environment.

Consequences of Misclassification

Overloading or overusing a crane beyond its intended classification can result in component failure, lead to structural fatigue, or compromise crane safety. This may cause more frequent repairs, costly unplanned downtime, or lost productivity during peak operations.

In regulated industries, it may also result in compliance issues or penalties. Adhering to proper overhead crane classifications helps you stay within the guidelines while protecting your team and assets.

For example, a Class B light-duty crane used in a busy fabrication shop where materials are lifted constantly throughout the day could cause excessive motor wear, brake failure, and eventually a complete system breakdown. Selecting the right crane classification upfront is a proactive decision that can protect your bottom line.

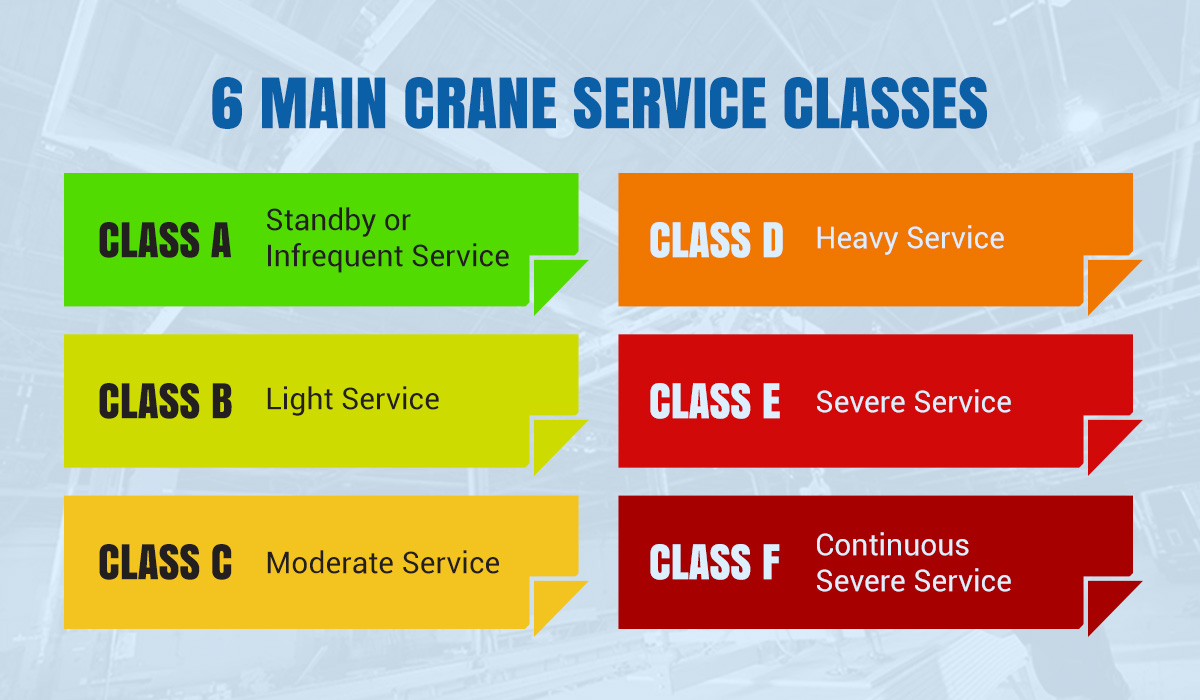

6 Main Crane Service Classes

The CMAA developed crane service classes to help users determine the safest and most economical crane for their operation. To do so, you must consider how much weight and how frequently the crane will be lifting and transporting materials. Once you have determined what needs to be moved and how often, a crane can be selected.

Class A: Standby or Infrequent Service

Class A cranes are used as standby or infrequent service cranes. These are systems intended for use at slow speeds and with long periods of idling between each lift. Class A cranes typically lift loads well below the rated capacity, but may occasionally be required to lift loads at the maximum capacity. This class often includes installation and maintenance cranes for applications involving public utilities, motor rooms, and transformer stations.

Class B: Light Service

Class B cranes are designed for light service requirements at slow speeds. Loads and duty cycle vary from empty to maximum capacity, with two to five lifts per hour averaging 10 feet in height. Cranes in this class are often used in light assembly facilities, repair shops, service buildings, and warehousing, where service requirements are light and slow.

Class C: Moderate Service

Class C cranes are designed for moderate service in an environment where the crane will need to handle loads averaging 50 percent of the rated capacity consistently, performing five to 10 lifts per hour. Class C service allows for an average lift height of 15 feet, and no more than 50 percent of lifting operations at the rated capacity. Most cranes are designed to meet Class C service requirements. This service often includes cranes used in manufacturing, machine shops, or paper mill machine rooms.

Class D: Heavy Service

Class D cranes are designed for heavy service applications. Class D cranes handle 50 percent of the crane’s rated capacity constantly throughout the workday, with up to 65 percent of lifting operations at full capacity. Class D service allows for an average of 10 to 20 lifts per hour, with heights averaging 15 feet. Class D cranes are designed to move loads quickly and are usually installed in locations where heavy equipment must be moved constantly. This service is often used for applications in heavy machine shops, foundries, fabricating plants, steel warehouses, container yards, and lumber mills.

Class E: Severe Service

Class E cranes are designed to handle loads approaching the rated capacity throughout their lifetime. Class E service allows lifts at or near their rated load capacity at an average of 20 lifts per hour. They can operate at any height, and they have few limitations on their workload per hour. These systems are often installed in scrap yards or production mills and are usually used when heavy items need to be transported regularly throughout the workday. Applications often include cement mills, lumber mills, fertilizer plants, and container handling. Class E and F cranes require more frequent maintenance and provide the highest reliability possible.

Class F: Continuous Severe Service

Class F cranes are the most powerful cranes available. These systems are similar to Class E cranes because they are designed to handle severe service. They also require the ability to handle loads approaching their rated capacity throughout their entire lifetime. The main difference between the two is that Class F cranes are designed for continuous severe service.

Often, Class F cranes are custom-designed for a specific function within a particular facility. They are built for ultimate performance and reliability, no matter how often they are used and regardless of their weight capacity. The most important factor for Class F cranes is that they can handle high-capacity loads with constant frequency. Because they are used continuously, cranes designed for Class F service must be designed with a focus on ease of maintenance. Class F cranes are often used in industrial settings, although very few industries need to meet a Class F service rating. These systems are challenging to design because they require the ability to handle the most extreme working conditions.

How to Select the Right Crane Classification

To choose the right crane classification for your operation, it’s essential to look beyond basic specifications like load capacity:

- Understand your lifting requirements: Identify the typical and maximum load weights your crane will handle.

- Calculate lift frequency: Determine how often the crane will be used during each shift. A higher number of lifts per hour indicates the need for a stronger service classification.

- Assess lift height: Consider the height at which materials will be lifted. Greater heights place increased demands on motors, cables, and braking systems.

- Consider environmental conditions: Account for any exposure to dust, moisture, heat, or corrosive substances. These conditions affect equipment durability and may require higher classification or specialized materials.

Manufacturers and material handling experts can also help you analyze your operational data and recommend the right solution. Before choosing, you may ask a few questions, such as:

- What is the average and maximum load weight?

- How frequently will the crane operate each hour and day?

- Will the environment affect the crane’s components?

- What level of maintenance access or downtime tolerance is acceptable?

Get the Right Classification for the Job

Matching your crane to the correct service classification is important to your operation’s long-term success. It ensures safety, improves productivity, and protects your investment by preventing overuse or misuse of equipment. However, with so many details and variables to consider, choosing the right system needs an informed approach.

That’s where Spanco can help. With decades of experience in material handling solutions, Spanco designs and manufactures overhead crane systems built to match your specific classification needs. Contact us today and let our experts guide you to the right crane for your operation.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!