Products

ERGONOMIC OVERHEAD CRANE SYSTEMS BUILT TO LAST

At Spanco, we have hundreds of pre-engineered overhead gantry lift cranes that we can completely customize to meet the requirements of your specific material handling application. Our certified engineers take pride in creating custom gantry systems for a broad variety of industries and applications. For your peace of mind, all Spanco cranes come with industry-best warranties.

From manufacturing, distribution, and maintenance to transportation, machining, and aeronautics, Spanco has helped thousands of facilities achieve measured improvements in:

Products

Overhead Ceiling Crane Systems From Spanco

Overhead material handling systems use a movable hoist to lift and move heavy materials horizontally through the facility's overhead space. Each system fulfills a particular purpose, such as:

- Moving materials around the facility.

- Transporting items from storage.

- Loading and unloading items from a truck.

- Moving parts through an assembly line.

Overhead cranes are ideal for these industries:

- Manufacturing

- Maintenance

- Machining

- Fabrication

- Transportation

- Aerospace

- Distribution

- Packing

If you need a material handling solution for your work, contact Spanco, a leading overhead crane manufacturer. We have many cranes available in our product inventory that have been engineered for quality and precision.

Workstation Overhead Bridge Cranes

Workstation bridge cranes are overhead material handling systems with parallel runways and a bridge that supports the hoist. Workstation cranes allow operators to lift and move loads with minimal effort in their work area. These lightweight systems have a capacities of two tons or less for repetitive load lifting and positioning. This type:

- Increases worker productivity by eliminating manual lifting.

- Makes the workflow easier by moving large loads quickly.

- Has a flexible modular design that can use new or existing support structures.

- Can supplement or replace your forklifts and jib cranes.

Spanco Workstation Bridge cranes are easy to move along the bridge to any point within the rectangle the two runways form. The low-profile steel track better uses the ceiling space while increasing the span. We have ceiling-mounted, freestanding, and headerless options, plus our Alu-Track® model.

Sturdy Mobile Gantry Crane Options

Gantry cranes have a beam supported by two legs at both ends and travel on swivel casters or rails to work a specific area. They use mechanical or manual power to lift and transport heavy loads and have the durability necessary to work for many applications. The advantages of gantry cranes include:

- Adjustable spans on some models to adjust to the load.

- Improved worker productivity and safety.

- No need for runways and support columns for installation.

- Flexible setup options for mobile units.

Spanco has several gantry crane models, including the A-Series, E-Series, PF-Series, and T-Series. We also have aluminum and single-leg gantry cranes. These models are easy to assemble and relocate to other areas in your facility. You can also lag bolt V-groove tracks and guide angles to the existing floor for fixed-path travel.

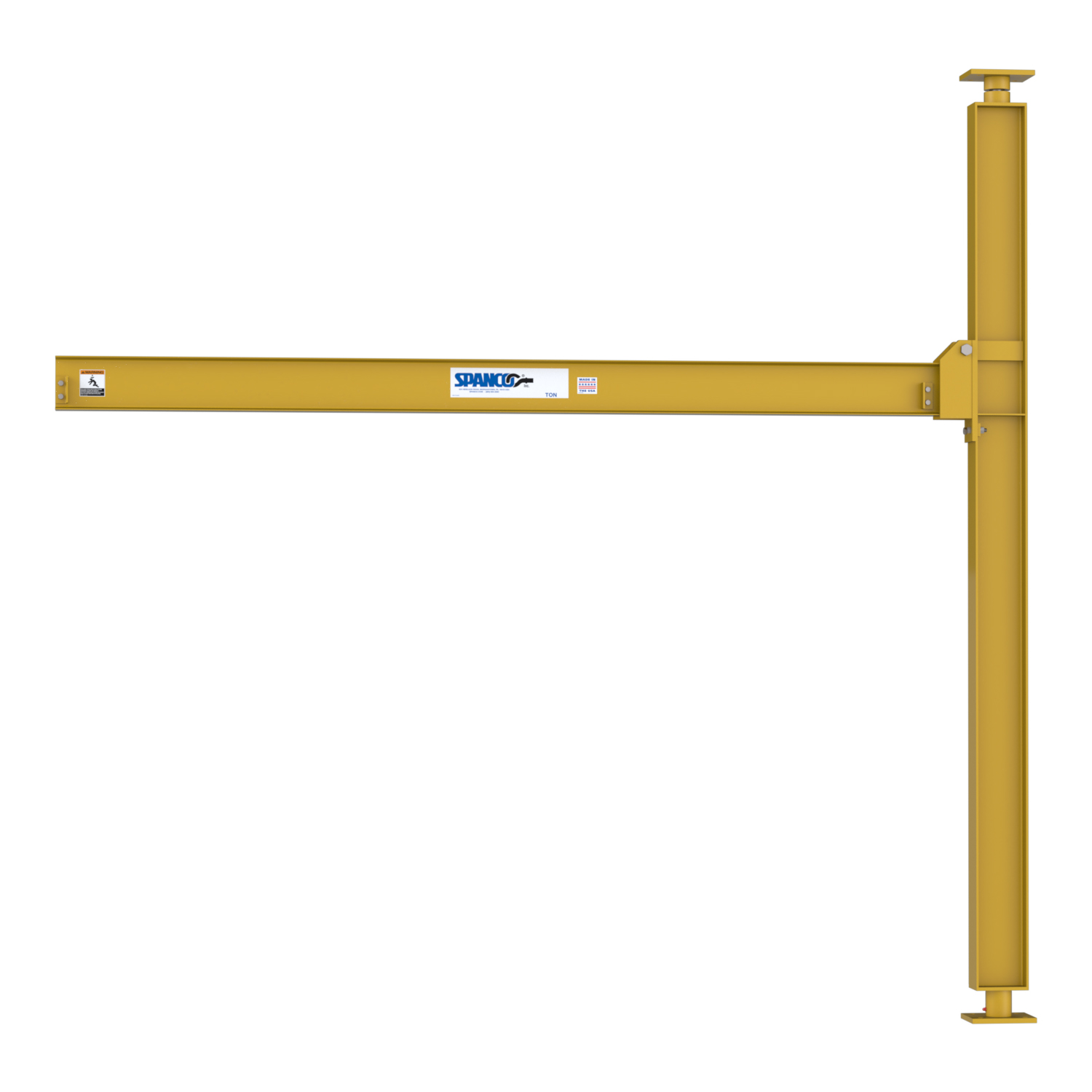

Articulating and Mast Style Jib Cranes

Jib cranes are an overhead crane system that completes repetitive lifting tasks in circular area of coverage. With a capacity of up to 15 tons, they can be used independently or with an overhead bridge crane to maximize production. The benefits of a jib crane include:

- Improved safety

- Increased worker productivity

- Reduced workplace injuries

- Simple operation

- Minimal maintenance requirements

- Maximized space utilization

Spanco Jib cranes transport materials in a 180- or 360-degree range around the support structure to move materials within a single workstation or between adjacent workstations. The boom can have additional hoists, manipulators or balancers installed. The jib crane models in our fleet include drop cantilever, full cantilever, freestanding articulating, wall-mounted cantilever, and more.

Monorail Material Handling Solutions

Monorail cranes move loads along a fixed path to relocate materials in a specific area. This simple design can be compatible with many workplace facilities—install it to a ceiling support structure or an independent freestanding structure. The benefits of this overhead crane system style are:

- Flexibility to be installed in any facility, including modifications as the facility expands

- Efficient load movement, easily avoiding obstacles for a straightforward path

- Simple controls run by an operator

- Tailored to the production line, including attachments

Our monorail overhead cranes for sale can be ceiling mounted or freestanding. These options are ideal for areas too restrictive for other types of cranes.

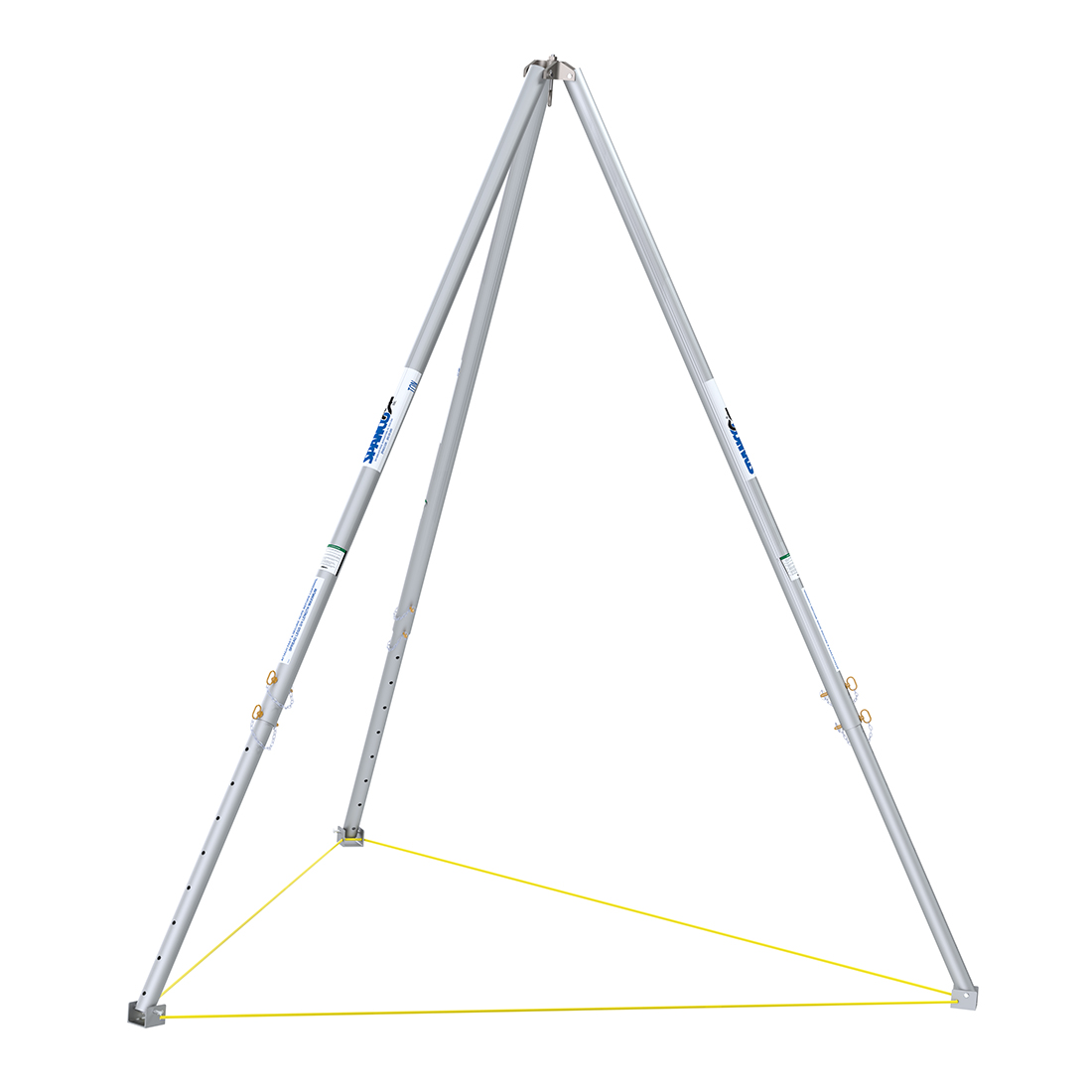

Industrial Tripods

Industrial tripods are sturdy frames with three legs that support loads. This mobile solution can be used anywhere and is best for outdoor locations inaccessible to forklifts and cranes and tight spaces without overhead structures. Though the unit is lightweight, it is mobile and has excellent lifting capabilities.

The industrial tripod by Spanco is easy to set up, requiring you to extend the collapsible legs to the desired height. Each leg can independently move in 6-inch increments to adjust to unlevel surfaces. The eyebolt freely moves and hangs perpendicular to the tripod to support the load. Our options include steel and aluminum frames in 1- and 2-ton capacities.

Material Handling Components Built to Last

Our components for gantry, jib, and workstation bridge cranes include motorization options. The motor allows the operator to eliminate the manual work with their crane system, promoting ergonomic comfort and workplace efficiency. Our options include:

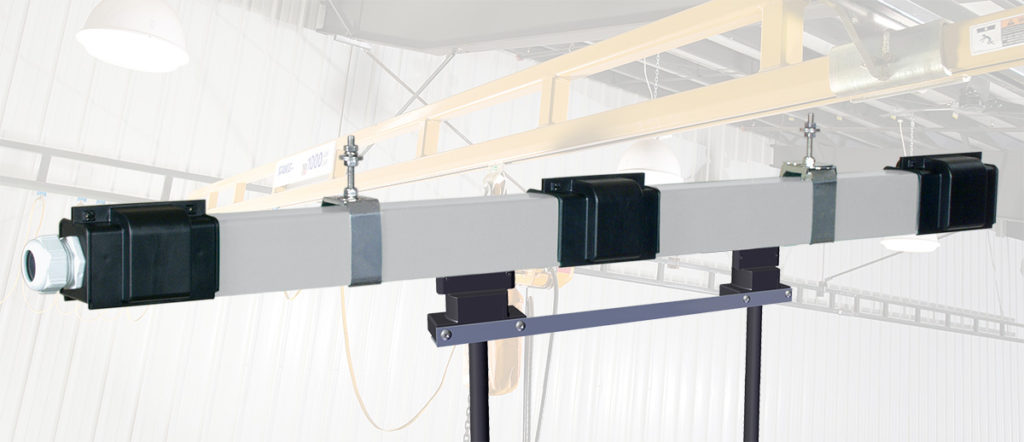

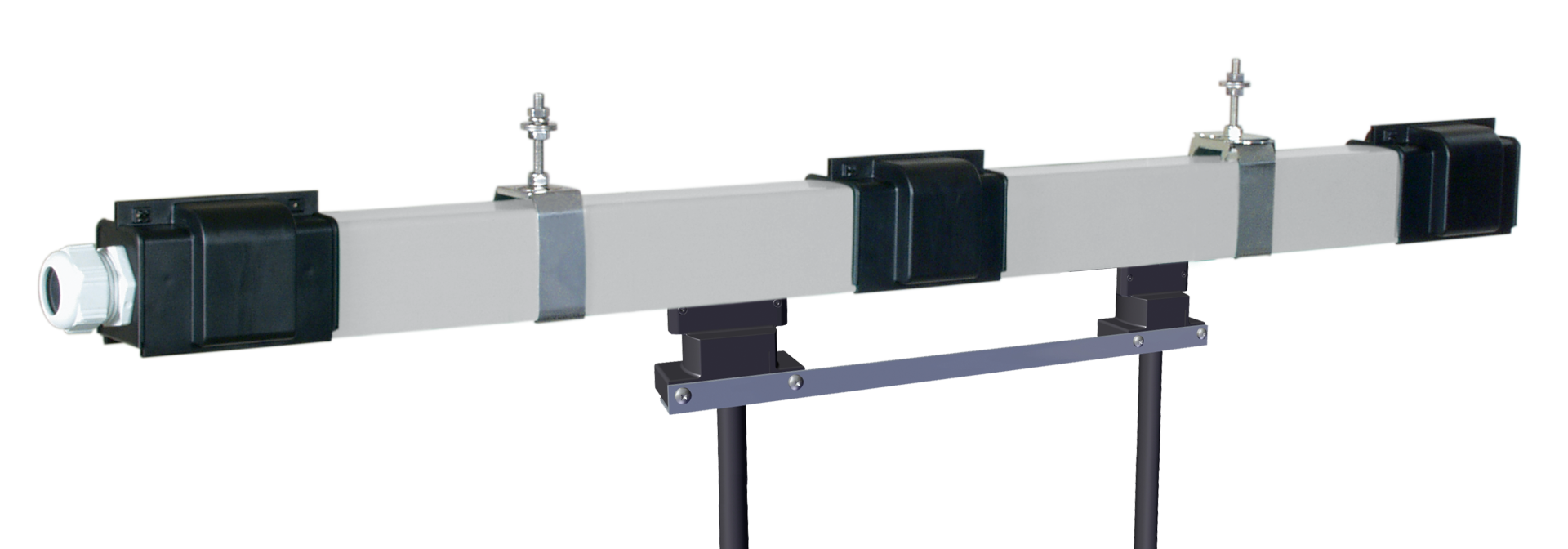

- Enclosed track tractor drive: These drives are made for workstation bridge and monorail cranes to motorize trolley and/or bridge travel. This product is best for applications where the load is challenging to move manually.

- Power drive kits: This product is compatible with the PF-Series in gantry cranes. It assists with high-volume and high-capacity travel on guide angles, crane rails, truly trackless, and V-groove tracks.

- Retrofit jib drives: The retrofit jib drive converts manual rotation to motorized rotation jib cranes. This solution is cheaper than purchasing a new powered crane.

View Our Products and Contact Us Today!

Spanco has the best overhead cranes on the market that will effectively move materials around your shipyard, construction site, manufacturing facility, or other workplace. Our overhead crane systems use:

- Corrosion-resistant industrial enamel paint

- Precision welding and tolerances for component alignment and stability

- Standardized wide flange beams and American I-beams

- Nuts, pins, and bolts with corrosion-resistant plating

We have thousands of pre-engineered options, and our certified engineers can tailor each crane to meet your application's specific needs. Each overhead crane also comes with the best warranties in the industry—10 years for manual systems and equipment and two years for motorized systems, equipment, paint, and finishes for non-aluminum components.

View our overhead crane systems in each product category. Use our system selector tool to see your options by system type, mounting method, movement, capacity, and more. For more information, find a representative near you or contact us online.