Breakdown of Overhead Bridge Crane Parts and Accessories

Mar 8, 2022

Whether you work in the construction industry, the automotive sector, or a different endeavor that requires lifting heavy loads, using an overhead crane in your facility can provide numerous benefits. Overhead bridge crane systems allow employees to quickly, easily, and safely move several tons of products and equipment throughout the building. There are various types of overhead bridge cranes to suit your applications.

If you’re planning to install an overhead bridge crane or want to learn more about certain parts of your existing setup, we’ve put together an extensive guide to help you learn more about typical bridge crane parts, accessories, and components. Additionally, we’ll cover a few points about the most common types of cranes. Keep reading for everything you should know about overhead cranes.

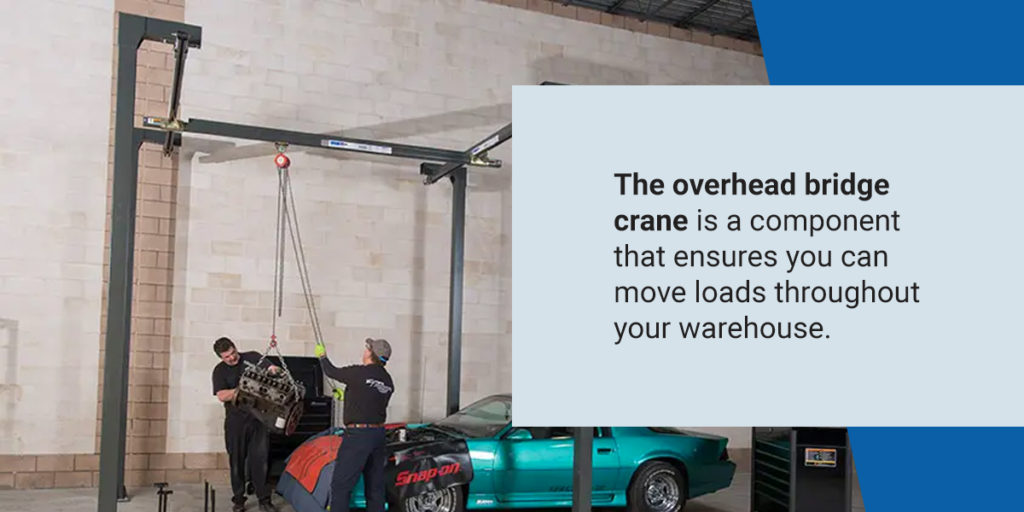

What Is an Overhead Bridge Crane?

Like many other kinds of equipment, cranes come in various shapes and sizes. An overhead crane features a system of different parts, including runways, bridges, hoists, and trolleys, to move loads throughout facilities. While many overhead bridge cranes are permanent structures installed in your building, movable overhead bridge cranes are also available for specific applications.

This heavy machinery can move thousands of pounds of product. Rather than ask workers to physically move heavy objects, crane operators can safely transport them without the risk of overexertion or other stress- or strain-related injuries. In particularly hazardous work environments, using an overhead crane to move materials from one place to another can significantly reduce workplace dangers, such as chemicals spilling or loads tipping over.

Even though overhead bridge cranes make the workplace safer, you and your employees can still encounter dangers during overhead crane operation. Per OSHA regulations, crane operators must follow specific regulations. As an example, crane operators should never leave their posts in the middle of operating a crane, even when they feel unable to continue the task at hand. The facility manager’s job is to ensure all crane operators are physically and mentally fit to operate the system safely.

As you explore options for overhead bridge cranes, you’ll want to consider a few aspects—your typical load capacity, your facility’s layout, your facility’s electrical system, and what materials you’ll transport using the crane. This way, you can make the safest and most logical decision for your building and employees.

Basic Overhead Bridge Crane Parts and Components

An overhead bridge crane consists of numerous parts and components. As a facility manager, it is important to know what each component is and what function it serves. This way, you can choose the best equipment for your application and avoid costly repairs, serious injuries, and excessive downtime due to a lack of knowledge. If you’re installing an overhead bridge crane for the first time, you’ll want to ensure your crane operators have adequate training on how each component works.

Below, you’ll find information about each type of overhead crane equipment part.

1. Hoists and Trolleys

The hoist and trolley work together to lift and move loads. As the hoist uses ropes or chains to lift, lower, and hold the load, the trolley connects the hoist to the bridge and allows it to move horizontally. Depending on the type of crane, the trolley can be located on the top or the bottom of the bridge. Additionally, both hoists and trolleys are available with manual or powered operation. These two components get your load from point A to point B.

2. Bridges

The bridge is the component that allows you to move loads along the length of your facility. This bridge is supported by the runways and includes several elements that allow it to function. Bridge components include:

- The bridge beam: The bridge itself is made of one or two beams supported at each end by the two runways.

- The end trucks: The end trucks are connected to both ends of the bridge and use wheels to carry it along the runways.

- The drive: The bridge drive is an optional electric component that powers the bridge’s back-and-forth movement over the runways.

A bridge can have one beam (single-girder) or two beams (double-girder), which you can choose according to your load weight needs. Additionally, bridges will vary in length according to the coverage needs of your application. If you plan on having overhead crane service throughout your facility, you can install multiple bridges on a single system.

3. Runways

A crane’s runways support the bridge, which holds the trolley and hoist. The runways are constructed from beams or enclosed track to allow the bridge to move along the length of the crane. They are installed throughout your facility, with runways placed to reach every area you need to cover. As the crane operator picks up loads with the crane, they can move the bridge back and forth over the runway. Then, they can move the trolley and hoist to place the load in the correct spot.

This part of the machinery will differ depending on what type of overhead bridge crane you install. High-capacity applications may require top-running bridge cranes, where the bridge runs on the top surface of the beams. Alternatively, bottom-running cranes may be more appropriate for applications with low headroom.

4. Columns

Sometimes, overhead bridge cranes will be built onto a building’s ceiling structure. These systems, known as ceiling-mounted cranes, don’t need support columns. If your building can’t support the weight of an overhead crane, you’ll have to install columns to provide enough support for the crane’s parts and components, as well as the intended loads.

The height of your system’s columns will depend on your lift height requirements and the facility’s vertical space. Additionally, the number of columns you need will depend on the size of the overhead crane system you need. A small bridge crane may need only four columns, but you can increase the coverage indefinitely by adding more columns.

5. End Trucks

A bridge’s end trucks ensure it can glide up and down the runway. One bridge will have one end truck on each end. These trucks attach directly on top or bottom of the runway and may incorporate drive wheels to help it move back and forth. Higher-capacity overhead bridge cranes may have larger end trucks or use multiple end trucks to distribute the greater weight.

6. Electric Connection

A crane’s electrical parts supply the power. Some bridge cranes, especially high-capacity systems, may require electrical power for the bridge, hoists, and trolleys.

An overhead bridge crane with electrical power will feature insulated conductor bars, a series of cables called festooning, and power boxes to supply power. In most cases, the electrical system will power several crane components. These parts include:

- The hoist: Electric chain or wire rope hoists require power to raise, lower, and hold loads.

- The trolley: A powered trolley uses electricity to move back and forth across the bridge.

- The bridge: If the trolley doesn’t require power, the bridge might. An electric tractor drive can move both the bridge and the load along the runways.

- The pendant: To operate electrical components, the crane operator might use a pendant, which is a handheld controller, to move loads. This controller is attached to the crane with a cable.

Having an adequate electrical system is arguably the most crucial part of operating your overhead crane. Many overhead bridge cranes can operate without electricity, but electricity can boost efficiency and make life easier for your operators and may be necessary in some applications. If applicable, be sure your facility’s electrical system is ready for connecting to your overhead crane before installation.

7. Controls

There are a handful of ways to control an overhead bridge crane. An electric-powered overhead crane will use an attached pendant controller, a wireless battery-powered remote, or a mounted control system. Typically, using a wireless remote will be the safest option, as crane operators can operate the crane from a distance. As a result, they won’t be in the system’s way during operation and will have a better view of where loads are traveling.

If you want to outfit your overhead crane system for compatibility with a wireless remote, you’ll need to install a receiver alongside the other electrical parts. This accessory allows the wireless remote to communicate with the crane. Depending on your facility’s needs, the wireless remote may have directional buttons for up and down, side-to-side, and other movement.

8. Bumpers

An overhead crane system can include bumpers to reduce stopping impact. During installation, you can place bumpers at almost any point you want to limit bridge movement. For example, placing bumpers at the ends of each runway rail will ensure the bridge comes to a softer stop. If your system includes multiple bridges, you can use bumpers to keep them separated.

Keep in mind that you’ll need to replace bumpers as they wear down to prolong your overhead bridge crane’s life.

9. Wheels

Numerous types of wheels help an overhead crane operate correctly. As we’ve mentioned, the bridge end trucks feature wheels that ensure they can move smoothly across the runways. Additionally, the trolley uses wheels to run back and forth across the bridge. This is a crucial part of the overhead bridge crane system, so you must ensure your wheels are always in working order.

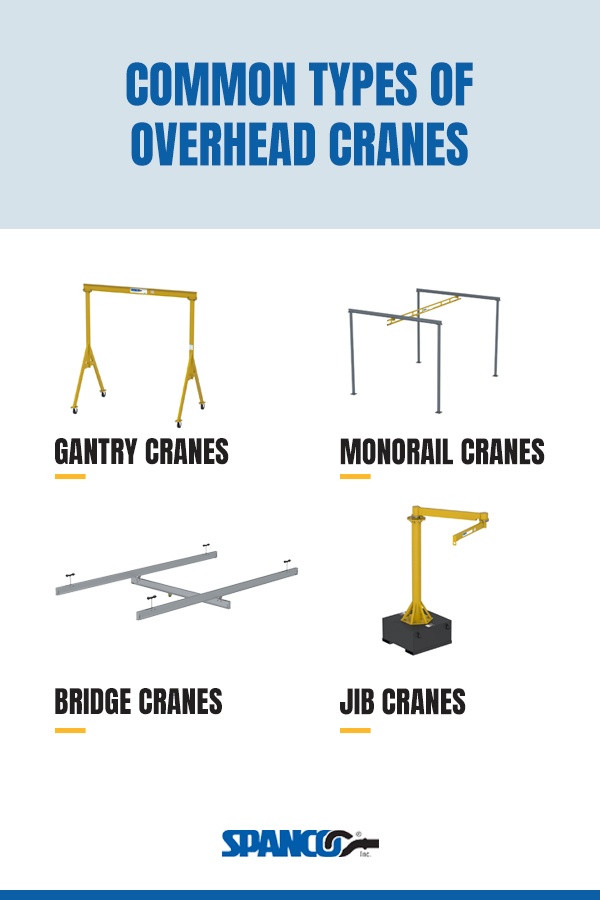

Other Types of Overhead Cranes

Overhead bridge cranes are commonly used in diverse industries and applications. However, not all applications are best served by a bridge crane. Other overhead cranes offer different arrangements and setups for different applications. If you’re installing a new overhead crane or want to know more about how your existing one works, continue reading to learn more about the most common types of overhead cranes.

Bridge Cranes

As we’ve mentioned, bridge cranes are a very common type of overhead crane. These cranes are installed inside manufacturing facilities, warehouses, and other buildings as permanent structures. A system of runways is installed throughout the building to provide material handling coverage to various locations. Then, bridges and end trucks are connected to the runways. Finally, hoists and trolleys are installed, and the electrical system, if present, is wired up.

Bridge cranes can use single-girder bridges constructed with one beam or double-girder bridges constructed with two beams. Typically, single-girder bridge cranes are ideal for light- to medium-duty applications, like Spanco’s enclosed track Workstation Bridge Cranes with 250-4,000 pounds of lifting capacity. Double-girder bridge cranes are typically used in applications that require capacities of 15 tons or greater, or when longer bridge spans or greater hook heights are needed.

Gantry Cranes

An overhead gantry crane is essentially a fixed bridge attached to two columns with wheels. Rather than traveling along runways, a gantry crane operates directly on the ground. Some extreme-capacity gantries, such as those used for container handling at ports, may have a two-beam bridge on top of columns that travel on a track. As with overhead bridge cranes, a hoist and trolley system lifts, lowers, and moves the load.

At Spanco, we offer four different gantry crane styles with options including adjustable heights, track mounting, power drives, and more.

Monorail Cranes

Much like a monorail train system, a monorail crane carries a load throughout a facility on a single suspended track. The monorail track is attached to the ceiling or a freestanding support structure. Depending on the length of the monorail crane setup, it may have multiple hoist and trolley systems, allowing operators to move multiple loads along the track.

Monorail cranes are well-suited for applications that require loads to be moved along a straight line. Many facilities that use monorail cranes do so above their assembly lines. However, monorail cranes can also incorporate curves and switches to access workstations in separate locations. Monorail cranes can even operate over a closed loop if needed.

Jib Cranes

A jib crane resembles an upside-down “L.” The most essential jib crane part is the individual beam, known as the boom, that supports the hoist and trolley to lift and move loads. The boom also supports any electrical components, air hoses, or other attachments. The boom can rotate 180 degrees or 360 degrees, allowing the crane operator to move loads along a semicircular or full circular path as needed.

Spanco offers jib cranes with capacities up to 15 tons. These systems are ideal for applications that require operators to move loads over short distances. If your facility needs a highly reliable crane system and you don’t need to move loads over large distances, a jib crane might be the right option.

View Our System Selector and Contact Us to Learn More

Spanco produces high-quality material handling overhead cranes and equipment for companies throughout the United States, Canada, and Mexico. The welders at Spanco are certified by the American Welding Society (AWS), so you can rest assured you’re getting reliable, top-grade products that can make your facility’s operations more streamlined and efficient. With Spanco manufacturing facilities on both coasts, you can quickly receive the equipment you need.

Are you unsure which kind of overhead crane you need? Try using our System Selector to find the best option for your needs. Choose the options and features you need, such as travel type and capacity, and the System Selector will identify which of our crane systems offer the best solution. Feel free to use it multiple times until you find a configuration that works best for you.

If you prefer to browse our availability of parts and components, optional accessories, and complete crane systems, you can explore our complete product line. For further help, fill out our contact form, and one of our representatives will reach out to you. Let Spanco be your source of quality, reliable material handling equipment and parts.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!