How to Choose the Right Jib Crane

Jun 18, 2025

Jib cranes are an economical solution for moving materials within individual work areas or from one work area to another. They can also serve as auxiliary lifting devices under overhead cranes. There are a variety of jib cranes on the market today, with styles ranging from entirely self-supporting to ceiling/bridge or wall-mounted.

When selecting a jib crane that matches your individual requirements, it’s important to think about your operation type, facility structure, cost of the unit and installation, and any necessary options, like motorized rotation, box track festooning, boom locks, and rotation stops.

How Do Jib Cranes Differ From Workstation Cranes?

Jib cranes and workstation cranes serve similar purposes but differ in their designs and coverage areas. A jib crane provides a circular coverage area, while a workstation crane provides a more expansive, rectangular coverage area. You can find enclosed-track workstation cranes in a monorail or bridge crane design.

A jib crane features a rotating boom that moves around a fixed point to cover a semi-circular or circular area. These cranes come in various designs to meet different applications and needs.

Types of Jib Cranes

Before choosing a jib crane, it’s important to understand how each type differs. Consider how each of the following types can meet your needs:

Freestanding

A freestanding jib crane features a mast with a rotating boom, and you can install it almost anywhere indoors or outdoors. The mast mounts to a portable concrete base, and it can typically rotate 360 degrees. Freestanding jib cranes from Spanco can handle 15 tons and reach up to 50 feet.

Mast-Style

Mast-style jib cranes bolt to the floor and the ceiling. A mast-style jib attaches to an upper support in the bracket or truss, eliminating the need for an independent foundation.

This type of jib crane can rotate 360 degrees, reach up to 20 feet, and handle up to 5 tons. If you choose a mast-style jib, you can opt for a drop-cantilevered or full-cantilevered model, depending on your building’s overhead structure.

A full-cantilevered jib’s boom mounts to the top of the mast, leaving maximum clearance beneath the crane. A drop-cantilevered jib features side-plate connections that enable you to lower the boom to specific heights on the mast. This is helpful for facilities requiring additional overhead clearance.

Wall-Mounted

Wall-mounted jib cranes attach to a support structure such as a wall, and they require no floor space or foundation. The 401 Series can rotate 180-200 degrees, reach up to 30 feet, and handle up to 5 tons.

You can choose between two different types of wall-mounted jib cranes — tie-rod-supported and cantilever. The tie rod-supported option is reinforced with a wall bracket and a tie-rod-supported boom. The trolley hoist can easily travel the boom’s full length because there is no support structure beneath it. The cantilever wall-mounted jib crane offers the most clearance above and below its boom. It’s also easy to install on any column or wall because it transmits less direct force.

Wall-mounted jib cranes are often the ideal choice for busy work areas because you can easily install them in individual workstations and maximize space utilization.

Articulating

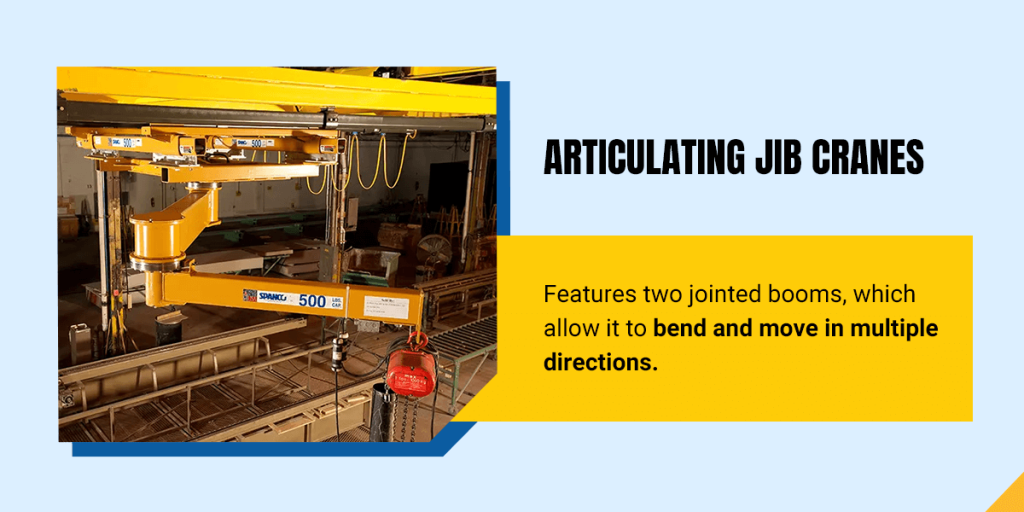

An articulating jib crane features two jointed booms, which allow it to bend and move in multiple directions. Its outer arm can rotate 360 degrees, and its inner arm can rotate 200 degrees. This makes it easier to move loads around obstacles, maneuver in tight spaces, operate in complex workspaces, and position loads with precision. It can reach into machinery and around corners and columns for easier access. Articulating jib cranes can handle up to 2,000 pounds and reach up to 16 feet.

You can choose this type of crane with wall-mounting, floor-mounting, ceiling-mounting, or bridge-mounting installation. An articulating jib can support any type of hoist, balancer, or manipulator.

Workstation

A workstation jib features an enclosed trussed track profile in place of a standard boom. It’s highly ergonomic and tends to operate faster than standard motorized models. Workstation jibs are typically ideal for lighter, repetitive loads and can handle up to 1,000 pounds and reach up to 16 feet. You can choose between freestanding, portable base, and wall-mounted workstation jib cranes.

How to Choose a Jib Crane

Proper jib crane selection depends on the following factors:

Application and Capacity

The maximum weight of the application should never exceed the rated capacity/design weight. The capacity rating is based on a design load that includes the capacity rating of the crane plus 15% of the capacity for the weight of the hoist and trolley and 25% of the capacity to allow for additional impact.

The deflection is based on a design load that includes the capacity plus 15% of the capacity for the hoist and trolley. Ensure your manufacturer is using design criteria that allow the least amount of deflection so as not to hamper the performance of the crane.

Height Under Boom (HUB)

The distance from the floor to the underside of the boom. It’s important to consider the size of the hoist and the amount of lifting distance when deciding on your HUB.

Overall Height

Consider the crane’s full height. Any attachments, such as electrical entry, should also be considered to provide full rotational potential and freedom from overhead obstructions.

Working Span

Working span is the distance the hoist trolley can travel along the jib crane’s boom. Also factor in the size of the hoist and the required trolley travel distance. The working distance or hook distance extends from approximately one-half the trolley length from the end of the beam to one-half the trolley length from the head assembly or vertical support member of the jib.

Boom Rotation

Consider your facility’s workspaces and how much rotation is necessary. Boom rotation impacts how far operators can move loads, which areas the crane can access, and how efficiently your workforce can complete tasks.

Power Requirement

How much power is necessary? Is power required for rotation, trolley, hoist, or all three? The standard powered jib rotation is approximately 1/2 R.P.M. Consider whether you will supply the power via bottom or top entry and if you will use an electric or air source.

Weatherization

Does the system or its electrical components need to be weatherized for outdoor use? This is an important consideration for safety and equipment longevity.

Installation

Can the crane be assembled easily to reduce cost? The location will also dictate the type of crane to be selected to ensure proper installation. Freestanding jibs require reinforced concrete foundations, which can cost more than the crane itself.

Because they are self-supporting, freestanding jib cranes are well-suited for outdoor use and can be fully weatherized.

Find High-Quality Jib Cranes From Spanco

Choosing the right jib crane can significantly boost efficiency and support your operational needs. Spanco offers a wide range of custom-built and pre-engineered jib cranes to fit your workflows, facility, and operational specifications.

Contact us to learn more about our jib cranes and how they can enhance your operations.

Linked Sources:

- https://www.spanco.com/product_category/workstation-bridge-cranes/

- https://www.spanco.com/product_category/jib-cranes/

- https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.1401

- https://www.spanco.com/product/401-series-wall-mounted-articulating-jib-cranes/

- https://www.spanco.com/product/mast-style-jib-cranes/

- https://www.spanco.com/product/200-series-mast-style-jib-cranes-full-cantilever/

- https://www.spanco.com/product/freestanding-jib-cranes/

- https://www.spanco.com/product_category/articulating-jib-cranes/

- https://www.spanco.com/product/workstation-jib-cranes/

- https://www.spanco.com/product/500-series-portable-freestanding-workstation-jib-cranes/

- https://www.spanco.com/product/500-series-portable-freestanding-workstation-jib-cranes/

- https://www.spanco.com/products/freestanding-jib-cranes

- https://www.spanco.com/product_category/mast-style-jib-cranes/

- httphttps://www.spanco.com/product_category/articulating-jib-cranes/

- s://www.spanco.com/product/401-series-wall-mounted-articulating-jib-cranes/

- https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.179

- https://www.spanco.com/contact/

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!