Best Cranes for Different Facility Layouts

Nov 4, 2025

An effective facility layout aims to provide the most efficient workflow and plant flexibility without disruption. There are several ways to ensure that manufacturing facilities design an effective layout that streamlines production and promotes a lean manufacturing process. Choosing the best crane for your facility layout is key to improving workflow and efficiency.

Process Facility Layouts

Process facility layouts arrange machines, tasks, and employees according to operations. Businesses with non-repetitive tasks and low production volumes often utilize this layout. Layout flexibility allows facility managers to place machines at several locations.

Process layouts are common in facilities that handle various product varieties or complete custom orders. These layouts often feature:

- Equipment grouped by function: Facility managers group work centers, equipment, and machines together based on their function. This arrangement allows for operational expertise and efficient equipment usage, but it also means that materials must travel between functional areas.

- Non-linear material flow: Process layouts feature complex, non-linear material flows. Products may visit several departments in a unique sequence depending on the job.

- Frequent layout changes: These layouts are inherently flexible, often undergoing frequent reconfiguration to accommodate new products, process improvements, or changes in demand. This dynamic environment requires material handling equipment that teams can easily relocate or reconfigure.

- Variable work patterns: Like the layout itself, work patterns are also highly variable. Workloads shift between departments based on production schedules and current orders. Some areas may have high activity surges while others are idle.

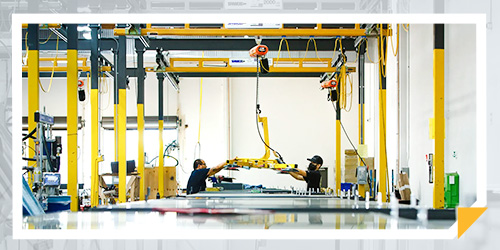

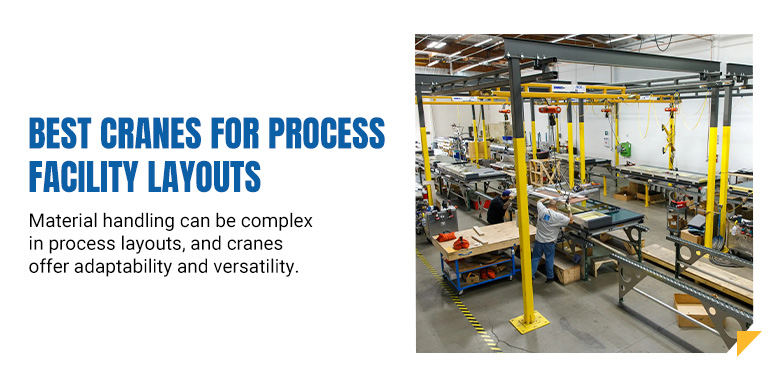

Best Cranes for Process Facility Layouts

Material handling can be complex in process layouts, and cranes offer adaptability and versatility. Workers tend to experience a lot of downtime because they are waiting for work or materials to arrive from another department. This type of layout requires flexible material handling equipment in order to follow multiple paths, move in any direction, and start and stop material flow as needed.

Top crane options include:

- Gantry cranes: Gantry cranes are movable and adjustable, making them a top recommendation. Products like Spanco T-Series Gantry Cranes are highly flexible and portable enough to reach all corners of your plant. They are totally relocatable, making them ideal for process layouts and future workflow changes. With adjustable height, span, and tread, these gantries are ideal for use through doorways, aisles, and under mezzanines or other overhead obstacles.

- Jib cranes: Jib cranes can benefit individual workstations in process layouts. This equipment provides localized, flexible lifting within specific work areas. These cranes can rotate to cover semi-circular or circular areas, and their compact footprint allows them to fit into tight spaces without interfering with other equipment.

- Portable solutions: Portable cranes and lifting solutions are highly valuable in dynamic process layouts. Workers can move this equipment when necessary to support layout changes and irregular material flows. Portable solutions can also handle various load types and sizes, increasing versatility.

Key Benefits of Process Facililty Layouts

Process layouts demand flexibility. Cranes must be versatile enough to suit multiple workstations and handle various load types. Prioritizing cranes that offer maximum flexibility and require no permanent installation ensures facilities can adapt quickly, efficiently, and cost-effectively to changing operational demands.

Fixed-Position Layouts

Facilities often use fixed-position layouts when the product is too fragile or too heavy to move through a production or process line. This includes manufacturers that produce items like ships, houses, or aircraft.

Fixed-position layouts meet the needs of a very particular type of manufacturing operation, and material handling is only used to move specific materials to and from fixed stations within the layout. Characteristics of these layouts include:

- Product remains stationary: In these layouts, products stay in one location throughout the entire production or assembly process. Managers organize all work activities and resources around the stationary product to ensure product stability and minimize risks of damage through handling.

- Materials and workers come to the product: With fixed-position layouts, the equipment, material, and workers must come to the production area, and the equipment is generally left on-site because it is too expensive or difficult to move. Though this process facility layout can be ideal for very heavy equipment, it can create a rigid layout for plants.

- Heavy, bulky, or fragile products: Fixed-position layouts are ideal for projects where the product’s size, weight, or fragility makes movement difficult or impossible. This layout brings everything to the product to ensure high-quality assembly.

Best Fixed-Position Facility Crane Selection

Fixed-position layouts require material handling equipment that can complete heavy lifting while offering mobility. Depending on the scope of the project, the best crane options include:

- PF-Series gantry cranes: A gantry crane offers flexible material handling for moving equipment from one work area to another. Spanco PF-Series gantry crane systems are a great option for fixed-position layouts, especially for those operations that need to move large or bulky materials. These supplemental lifting systems will help facilities free up existing overhead cranes and provide a clear, wide passage underneath the gantry for personnel, vehicles, and machinery. They are also extremely flexible because they don’t travel along a fixed path, and for operations that produce large products, these cranes are durable and precise enough to lift even the heaviest parts.

- Heavy-duty jib cranes: Heavy-duty jib cranes are well-suited for fixed-position layouts where precise, localized lifting is necessary. Teams can mount these cranes to the floor or a column and leverage the rotating arm to move materials and components into place. Robust construction supports substantial load handling, and their construction makes them suitable for small spaces or alongside other equipment.

- Overhead bridge cranes: Overhead bridge cranes offer facility-wide coverage. Large manufacturing bays or assembly halls can utilize these cranes for precise, three-dimensional material movement. These cranes feature elevated runways and a moveable hoist, which is ideal for projects requiring frequent component lifting and positioning.

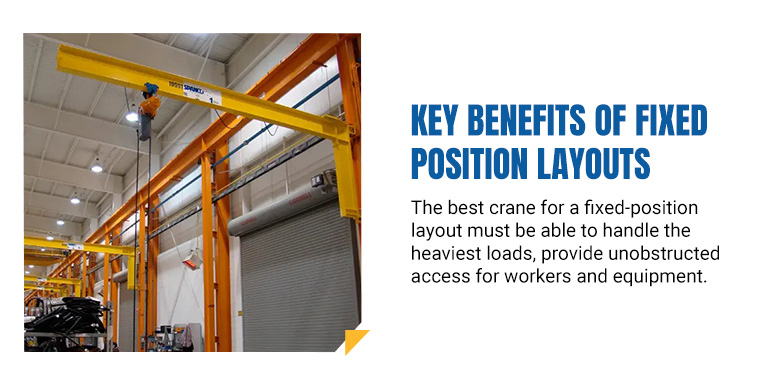

Key Benefits of Fixed-Position Layouts

The best crane for a fixed-position layout must be able to handle the heaviest loads, provide unobstructed access for workers and equipment, and work seamlessly alongside existing systems.

Products in fixed-position layouts are often extremely heavy, bulky, or difficult to move, so cranes must be capable of lifting and positioning project components with precision while keeping floor space clear for personnel, tools, equipment, and vehicles to move freely around the product.

Manufacturing Assembly Line Layouts

Manufacturing assembly line layouts enable standardized, linear processes to enable high-volume production and ensure consistency and efficiency. Machines and workstations are in a specific order according to the product’s production flow.

Assembly line layouts streamline production and reduce backtracking with predictable material flows. These layouts ensure high efficiency, consistency, and scalability by leveraging characteristics like:

- Linear workflow patterns: Straight, linear workflows define assembly line layouts. Products move from one station to the next sequentially, with each workstation performing specific tasks. This predictable flow is ideal for standardized and high-volume production environments.

- Repetitive lifting tasks: With each station on the assembly line completing the same task repeatedly, material handling requirements are consistent. Lifting, positioning, and moving materials are repetitive. Cranes and lifting devices in these settings often offer speed, reliability, and ergonomic support to maintain steady production rates.

- Rectangular coverage areas: Due to the linear workflow, most assembly line layouts use rectangular coverage to maximize space utilization and efficiency. Material handling equipment must provide coverage along the entire length of the assembly line to serve every station without interfering with adjacent equipment or workflows.

- Material flow between stations: Material flow is highly directional in these layouts. Components move between stations, often through the use of conveyors, cranes, or automated guided vehicles. This flow aims to minimize delays and ensure uninterrupted work progression.

Best Crane Solutions for Manufacturing Assembly Line Layouts

Workstation bridge cranes are ideal for assembly line layouts because they provide precise overhead lifting along defined rectangular areas. These cranes allow for easy, ergonomic material lifting and moving directly over each workstation. Systems are also modular, making them easy to install, expand, or reconfigure as assembly lines evolve. Ceiling-mounted bridge cranes offer enhanced flexibility and allow for maximum floor space.

Monorail systems are also suitable for linear material transport. This equipment is highly efficient for transferring components between stations along a predetermined route. Monorails can also be space-saving, offering ceiling-mounted or freestanding varieties.

Key Benefits of Manufacturing Assembly Line Layouts

Manufacturing assembly line layouts require material handling equipment to support product flows and workstation setups. Crane solutions must enhance productivity, safety, and workflow consistency in manufacturing environments. Solutions should offer seamless integration with existing processes, require minimal manual effort, and feature smooth, ergonomic movements to protect workers and minimize downtime.

Warehouse and Distribution Layouts

These facilities store, retrieve, and move goods with multidirectional flows. Their layout structures are often open and leverage racking systems, wide aisles, and shelving. Work patterns are often dynamic, with peaks and valleys in activity.

Warehouse and distribution layouts prioritize storage efficiency, rapid access, and adaptability to changing inventory and demands. These layouts feature characteristics such as:

- High-density storage areas: These layouts aim to maximize storage space. Layouts achieve high storage densities with high shelving units and comprehensive racking systems. Material handling equipment must be able to navigate aisles seamlessly and reach great heights to access all products.

- Order picking operations: A central function of warehouse and distribution layouts is order picking. Layouts must enable fast and accurate product retrieval, often utilizing dedicated picking zones, movement paths, and staging areas. Equipment must integrate into these workflows to enhance efficiency.

- Loading dock integration: Loading docks connect warehouses and distribution centers to suppliers and shippers. Layouts must ensure smooth integration of loading docks to minimize travel and bottlenecks. Dock equipment must be able to handle heavy loads and bulky shipments.

- Inventory management needs: Accurate inventory management is essential in these facilities. Layouts should support real-time inventory tracking and efficient stock rotations. Facilities must leverage equipment that enables fast product locating and counting to prevent delays and reduce errors.

Best Cranes for Warehouse Crane Layout Optimization

Because these facilities incorporate multiple functions, the layout and equipment must reflect the needs of various workstations. Warehouse optimization involves leveraging material handling equipment for various locations in the facility:

- Workstation bridge cranes: Workstation bridge cranes are suitable for order fulfillment areas. They can handle repetitive lifting, packing, and assembly tasks. Bridge cranes offer overhead access for moving bulky and heavy items with minimal effort.

- Monorail systems: Dock-to-storage transport operations can leverage monorail systems for high efficiency along fixed routes. These solutions can guide the movement of pallets, containers, and large items. This setup streamlines material flows from receiving to storage and vice versa.

- Gantry cranes: Outdoor loading areas benefit from gantry cranes. Yards and staging areas can leverage this equipment to handle oversized shipments when loading or unloading trucks, shipping containers, and railcars.

- Jib cranes: Jib cranes are suitable for localized lifting, such as truck loading and unloading. The rotating arm on these cranes provides flexibility for moving goods between truck beds and docks while reducing manual lifting effort.

Key Benefits of Warehouse and Distribution Layouts

Material handling equipment for warehouse and distribution layouts must maximize vertical space utilization, reduce forklift dependency, and improve order accuracy and speed. Order fulfillment and optimized storage are fundamental aspects in these facilities, so equipment must support operations by enhancing driver safety, boosting workflow efficiency, and empowering higher throughput operations.

Maintenance and Repair Facility Layouts

Maintenance and repair facilities are defined by their flexibility, adaptability, and readiness for unpredictable and often custom work. These layouts prioritize open space and functional grouping to support constantly changing workloads.

These facilities must be ready to handle a wide range of tasks, from emergency repairs to routine inspections for equipment of varying sizes and complexities. Material flow is often unpredictable, so layouts must consider:

- Equipment positioning requirements: Maintenance and repair facilities must accommodate a large variety of equipment types, sizes, and shapes. Layout designs should enable easy movement and precise equipment positioning within service bays.

- Component removal and installation: A core function of maintenance and repair facilities is removing and installing heavy or complex components, like transmissions, engines, and large assemblies. Layouts must support the use of cranes and other materials handling equipment to access, extract, and install components efficiently and safely.

- Variable lifting points: Unlike other process layouts, maintenance and repair layouts must account for unpredictable lifting points. Cranes and hoists must be able to reach various positions, including inside, above, or around the component receiving service.

- Service bay configurations: Service bays are the heart of these facilities. Bays are often open and modular, with the ability to reconfigure the space as necessary to accommodate different types of work. These areas must be able to support routine and emergency tasks efficiently.

Best Cranes for Maintenance and Repair Facilities

Similar to warehouse and distribution layouts, maintenance and repair facilities benefit from implementing zone or task-specific equipment. Ideal options include:

- Jib cranes for individual service bays: Jib cranes are a staple in these facilities because the rotating arms allow workers to reach various access points and different heights as demands change. This equipment can complete repetitive tasks like part installation while requiring minimal physical space.

- Workstation bridge cranes for component handling: Areas handling components that need to move across wide areas or between multiple workstations can benefit from workstation bridge cranes. This equipment can lift, transport, and position components along parallel runways to reduce manual handling.

- Gantry cranes for large equipment positioning: Gantry cranes are highly efficient at positioning large or heavy equipment. This equipment can straddle oversized machinery and vehicles for easy movement. With enhanced mobility and high lifting capacities, gantry cranes can aid in relocating equipment, loading or unloading trucks, and supporting major overhauls.

- Articulating jib cranes for tight spaces: Articulating jib cranes deliver the flexibility and compact nature necessary to enable various operations. This equipment features multiple pivot points, allowing the arm to reach hard-to-access areas. It is valuable for lifting tasks in crowded service bays, inside equipment enclosures, or around machinery.

Key Benefits of Maintenance and Repair Facility Layouts

Cranes that support maintenance and repair facility layouts offer precise positioning and access to confined spaces while reducing downtime. Lifting equipment must offer smooth, controlled movement to reduce damage risks. The right systems can operate in crowded areas efficiently while maintaining worker safety.

Multilevel and Mezzanine Facilities

Multilevel and mezzanine facilities are distinct from other process facilities because they maximize vertical space with multiple floors or platforms. These layouts incorporate elevated walkways or partial floors and allow goods, people, and processes to move between floors.

These facilities often require specialized equipment due to their unique setup. Multilevel facilities feature several key characteristics:

- Multiple working levels: These facilities consist of two or more levels or tiers of usable space. Whether incorporating full floors or partial platforms, these designs allow for the separation of activities or increase storage capacity, depending on facility needs. Material handling equipment must be able to serve each level, or each level must have its own equipment to maintain efficiency.

- Height restrictions: While these layouts take advantage of vertical space, they also have height restrictions. Each level has a limited ceiling height, which means all equipment must be able to operate within defined clearances.

- Complex material flow patterns: Material flow is often more complex in these facilities compared to those with other process layouts. Products, people, processes, and equipment can move vertically and horizontally. Movements require precise coordination, and material handling equipment must integrate into these workflows seamlessly.

- Structural limitations: Elevated platforms and mezzanines often require support columns, beams, or other structural building elements. Layouts must account for load-bearing limits and restrict the placement of equipment and goods to ensure safety. These limitations can also impact the type of cranes and other equipment that a facility can install.

Best Multilevel Facility Cranes

Each crane in a multilevel layout should address the unique challenges of the facility. Ideal multilevel facility cranes include:

- Low-headroom workstation cranes: Low-headroom workstation cranes are ideal for environments with limited vertical clearance. They feature compact components that maximize lifting height within tight spaces.

- Under-running bridge cranes: Underhung cranes mount beneath runway beams to enable operation in environments with restricted overhead space. This design allows the crane to travel under a mezzanine, providing full coverage along each level’s length and width.

- Wall-mounted jib cranes for each level: This equipment is a practical solution for localized lifting on multiple levels. Teams install these jib cranes onto structural walls or supports. Workstations with repetitive lifting can implement wall-mounted jib cranes to save floor space and serve independent areas.

- Adjustable gantry cranes for variable heights: Adjustable gantry cranes are highly versatile, allowing teams in multilevel facilities to modify heights to suit various elevations. Workers can wheel these cranes and position them to complete lifting tasks on the main floor, on mezzanines, or between levels.

Key Benefits of Multilevel and Mezzanine Facilities

Multilevel and mezzanine facilities maximize the use of vertical space. Material handling equipment must efficiently serve multiple levels and accommodate height restrictions. Adjustability and flexibility are crucial for navigating these unique layouts.

Design Framework: Matching Cranes to Layout

When matching cranes to your layout, it’s important to consider key assessment factors, including:

- Coverage patterns: Choose cranes with coverage patterns that match your workflows. Bridge cranes suit rectangular areas, while jib cranes offer localized operation in circular spaces. Monorail systems are best for linear workflows and point-to-point movement on fixed routes.

- Load capacity requirements: Assess the maximum and typical weights your workers will be lifting. Select a crane with sufficient capacity for your heaviest loads, factoring in safety margins and potential future increases in load size or frequency.

- Available space and headroom: Evaluate floor space, aisle widths, and vertical clearance. Low-headroom cranes or wall-mounted options may be necessary in tight or multilevel environments, while open layouts can accommodate larger, overhead systems.

- Building structural support: Determine whether your facility can support a crane’s weight and forces. Some models may require reinforced floors, beams, or columns, while others are freestanding and don’t require building support.

- Future flexibility needs: Consider whether your layout needs will change in the foreseeable future. Portable and adjustable cranes are best for facilities with evolving needs, and can make transitions easier when expanding or reconfiguring layouts.

- Budget considerations: It’s important to balance purchasing prices with long-term value. Think about installation and maintenance costs when establishing your budget. Sometimes, adopting a higher-capacity or more adaptable crane can save money by reducing future spending on replacements or reconfigurations.

Spanco Solutions for Plant Layout Flexibility

Whether you incorporate a process or fixed-position layout, you need a system that can help facilitate plant layout flexibility without compromising productivity or interrupting workflow. Gantry cranes help you set up your plant floor layout the way you need to, taking into account possible future layout modifications such as location changes or new production processes. By adopting material handling equipment that turns your plant manufacturing processes into a more streamlined, flexible environment, you help boost productivity and decrease downtime.

We at Spanco, Inc. understand the importance of heavy material handling in the manufacturing process. With more than four decades of industry experience, our plant layout solutions are geared toward flexible heavy material management, allowing you to adapt to industry changes and business growth. For more information, contact us online today. One of our professional team members will discuss the best options for your manufacturing facility.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!