Incorporating Flexibility for Process and Fixed-Position Layouts

Mar 27, 2024

The goal of an effective facility layout is to provide the most efficient workflow and plant flexibility without disruption. There are several ways to ensure that manufacturing facilities design an effective layout that streamlines production and promotes a lean manufacturing process. Depending on the operation, there are three basic facility layouts used in manufacturing:

- Product Layout

- Process Layout

- Fixed-Position Layout

Fixed-Position and Process Layouts are more complex than Product Layouts, as items are either immovable or constantly changing. All of these different layouts come with the objective of improving workflow and efficiency. But, all three layouts come with their own set of disadvantages, and flexibility is often a major concern.

Gantry Cranes

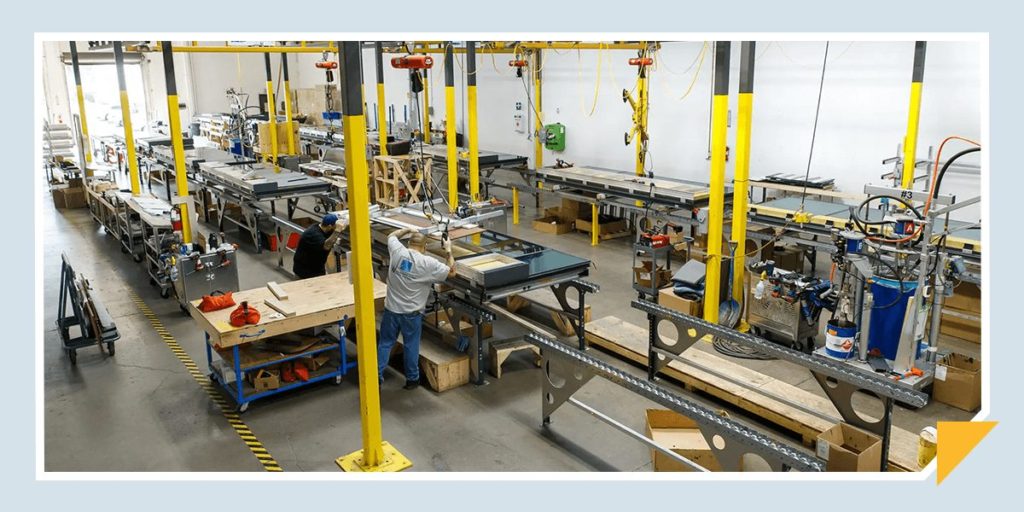

Gantry cranes are a popular material-handling solution for many industries, and they can accommodate practically any operation and facility layout. Superior portability and adjustability make them a perfect solution for facility layouts that can be especially rigid. For manufacturing plants using a Fixed-Position or Process Layout Design, incorporating subtle changes in material handling can provide flexibility and improve efficiency without having to rearrange an entire operation.

Gantry cranes can be customized to fit your manufacturing needs, as well as your plant capacity. You can choose a gantry based on your plant layout requirements:

- Track-mount gantry: Incorporating a fixed track where your gantry can move, motorized or manually, can significantly improve rigid operations.

- Relocatable gantry: A fully relocatable gantry gives your process layout more freedom and flexibility, allowing you to adapt to workflow or location changes.

- Portable gantries: A portable gantry gives you optimal plant layout flexibility so you can move more materials and get more work done.

- Adjustable gantries: Accommodate gantries to your workflow and process facility layout by adjusting the gantry’s height, tread, and span.

Process Layouts

A manufacturing plant utilizing a process layout arranges machinery according to its functions. While this can prove productive, it doesn’t always aid plant layout flexibility.

Process Facility Layout Challenges

For process layouts, jobs don’t flow in an orderly fashion and backtracking is a common problem. Workers tend to experience a lot of downtime because they are waiting for work or materials to arrive from another department. This type of layout requires flexible material handling equipment—such as forklifts—in order to follow multiple paths, move in any direction, and start and stop material flow as needed.

For the Process Layout design, material handling is more of an afterthought, only used to move parts and processes to the product, rather than the other way around.

How Gantry Cranes Can Help With Plant Layout Flexibility

To avoid the use of expensive, cumbersome, and high-maintenance forklifts, or to add to a pre-existing forklift fleet, consider incorporating a three-way adjustable manual gantry crane, which can be easily moved under load from any one part of a facility to another.

Spanco T-Series

Spanco T-Series Gantry Cranes are highly flexible and portable enough to reach all corners of your plant.

They are totally relocatable, making them ideal for Process Layouts and future workflow changes. With adjustable height, span, and tread, these gantries are ideal for use through doorways, aisles, and under mezzanines or other overhead obstacles. What’s more, they can be used as a supplementary material handling solution to reduce downtime and ensure continuous workflow.

Fixed-Position Layouts

Fixed-Position Layouts are often used when the product is too fragile or too heavy to move through a production or process line. This includes manufacturers that produce items like ships, houses, or aircraft vehicles. The advantage to Fixed-Position layouts is low fixed costs, while the disadvantage is high variable costs.

Fixed-Position Layout Challenges

With Fixed-Position Layouts, the equipment, material, and workers must come to the production area—and the equipment is generally left on site because it is too expensive or difficult to move. Though this process facility layout can be ideal for very heavy equipment, it can create a rigid layout for plants.

Fixed-Position Layouts were designed to meet the needs of a very particular type of manufacturing operation, and material handling is only used to move specific materials to and from fixed stations within the layout. For this reason, a gantry crane is also the perfect solution for flexible material handling or as a supplementary system to move equipment from one work area to another.

The Value of Gantry Cranes in Fixed-Position Layouts

The right type of gantry crane honors your plant’s fixed process layout. Here, the gantry crane isn’t used to move the product to the material; it’s used to move the material to the product.

Spanco PF-Series

With capacities up to 20 tons, heavy-duty gantries like a wide flange or Spanco PF-Series Gantry Crane systems are a great option for Fixed-Position Layouts, especially for those operations that need to move bulky or large materials.

These supplemental lifting systems will help facilities free up existing overhead cranes and provide wide, clear passage underneath the gantry for machinery, vehicles, and personnel. They are also extremely flexible because they don’t travel along a fixed path, and for operations that produce large products, these cranes are durable and precise enough to lift even the heaviest parts.

How Spanco Cranes Can Help With Flexibility

Virtually all gantry cranes are relocatable, making them ideal for future workflow changes or as a supplementary solution to prevent lagging in the production process. As technology constantly grows and changes, it’s important for manufacturers to have the flexibility and versatility they need to consistently improve their operations and streamline their production processes. Redesigning an entire production facility is usually not an option for most companies, no matter which type of facility layout they have incorporated. Rather than redesigning an entire manufacturing facility to streamline a production process and eliminate downtime, incorporating a flexible material handling solution is a much more economical way to redefine the entire flow of your operation and introduce a new layer of flexibility.

Spanco Solutions for Plant Layout Flexibility

Whether you incorporate a process or fixed-position layout, you need a system that can help facilitate plant layout flexibility without compromising productivity or interrupting workflow. Gantry cranes help you set up your plant floor layout the way you need to, taking into account possible future layout modifications such as location changes or new production processes. By adopting material handling equipment that turns your plant manufacturing processes into a more streamlined, flexible environment, you help boost productivity and decrease downtime.

We at Spanco, Inc. understand the importance of heavy material handling in the manufacturing process. With more than four decades of industry experience, our plant layout solutions are geared toward flexible heavy material management, allowing you to adapt to industry changes and business growth. For more information, contact us online today. One of our professional team members will discuss the best options for your manufacturing facility.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!