To Motorize or Not to Motorize

Jan 10, 2020

One of the many benefits of Spanco products is the motorization package option. As a Regional Sales Manager, I have many customers ask me whether or not they should consider motorization when purchasing a crane. In this article, I will go over some of the benefits of motorization and some applications where motorization would be useful. I hope this article provides the information you need to decide if motorization is right for your material handling application.

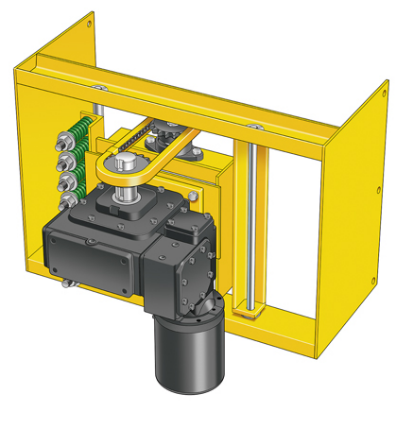

We offer motorization on many of our Spanco Jib, Gantry, and Workstation Crane Systems. Motorization allows a worker to use a traveling pendant, or more commonly, a wireless remote to operate a crane when motorization is required. But how do you determine when motorization is necessary? Many people recognize crane capacity as a determining factor when considering motorization, but there are other factors as well, including the application and the size of the system. Just because a crane lifts 10 tons doesn’t necessarily mean it needs to be motorized if the application and the size allow the crane to be used manually.

Applications

The specific application where a system will be used is an important factor when considering motorization. One example of an application that may require motorization is a situation where the worker cannot move the load under the hoist manually due to the pure physical size of the piece being handled. If the load prevents a worker from accessing a safe point to move the system manually, he or she will require a motorized system.

Another scenario requiring motorization occurs when a load must travel to an area blocked by a physical obstacle, such a rack, machine, or other large object. In this type of application, motorization allows the worker to control the movement remotely and navigate the load over or around the obstruction. Our Spanco Workstation Bridge Cranes or

PF-Series Gantry Cranes are often used in this type of application where there may be multiple work areas with machines or equipment between them.

System Size

Jib Cranes

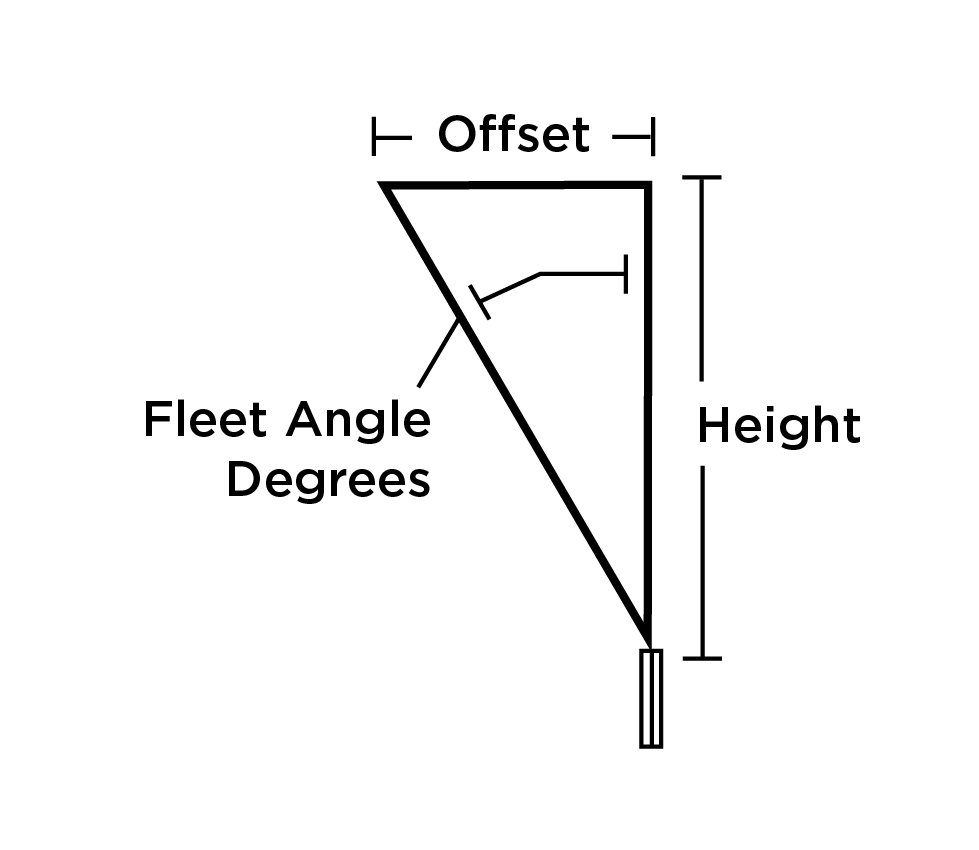

Motorization can also be necessary when workers need to rotate the jib crane with the load close to the mast. Because the leverage is lower when the load is closer to the mast, the force needed to rotate the boom may be too great for a worker to move it manually. A motorized jib will make the system much more user-friendly and allow the worker to rotate the load without the risk of over-exertion.

Changing Your Mind

One of the beneficial design features of some Spanco material handling systems is the ability to motorize a system after installation. If you purchase a Spanco Workstation System without a motorization package and you realize later that your application isn’t suited for manual operation, you can easily add the motorization option.

At the end of the day, safety and worker ergonomics should be the focus when it comes to applying material handling products to all lifting applications. If adding motorization to your system will improve worker safety and efficiency, it could be a great option for your Spanco Jib, Gantry, or Workstation Crane. If you have any questions, reach out to your local Spanco regional sales manager to help you apply our product for your material handling needs.

About the Author

Tim Bambrick holds a degree in Mechanical Engineering from Thaddeus Stevens College and has spent 15 years in the material handling, fall protection, and safety industries. Tim has extensive industry experience ranging from working as an Engineer to working in a product development role for multiple companies. Tim is currently the Regional Sales Manager for the Mid-Atlantic and Eastern Canada territory for both Spanco and Rigid Lifelines.

Categories

Share this post

Contact us

Looking for the perfect fall protection equipment? Let us help!