Posts by developer

How to Choose the Right Jib Crane

Jib cranes are an economical solution for moving materials within individual work areas or from one work area to another. They can also serve as auxiliary lifting devices under overhead cranes. There are a variety of jib cranes on the market today, with styles ranging from entirely self-supporting to ceiling/bridge or wall-mounted. When selecting a…

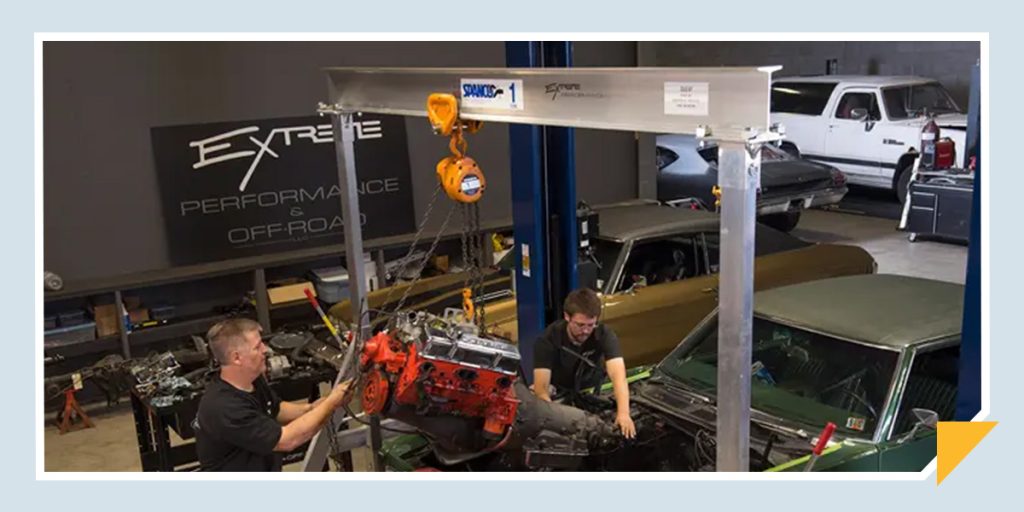

Read MoreThe Benefits of an Aluminum Gantry Crane Over an Engine Hoist

One common tool found in many automotive garages is the engine hoist. While engine hoists serve their purpose, they can be limiting in their versatility and portability. Many operators and warehouse managers choose aluminum gantry cranes to overcome these issues. These cranes provide a more efficient, stable, and versatile solution — perfect for a broader…

Read MoreMaterial Handling Basics: What Is a Gantry Crane?

A gantry crane is an overhead crane with one or two legs that move on wheels, tracks, or rail systems. Smaller gantry systems run on wheels or casters that can move throughout a facility for light fabrication work or maintenance. Larger gantry systems travel on rail or track embedded in the ground, typically running in…

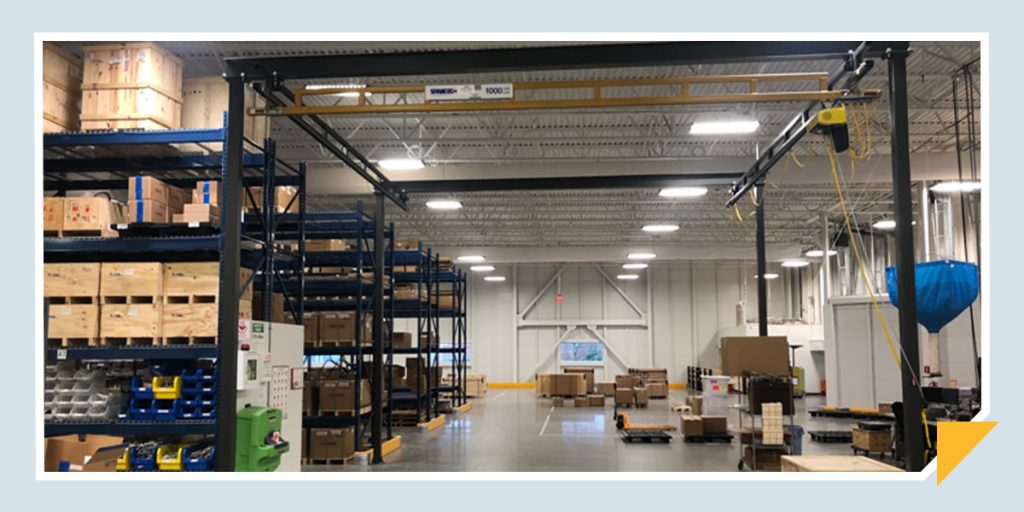

Read MoreMaterial Handling Basics: What Is a Workstation Crane?

Workers in manufacturing and assembly often need a safe method to move heavy materials. Workstation cranes are an ergonomic and user-friendly solution. They are typically used to support manufacturing activities, transporting materials or components from one process to the next. Workstation cranes are used in a variety of applications to support processing and handling throughout…

Read MoreAre Your Runways Aligned?

Proper crane runway alignment is crucial to meeting performance requirements and ensuring safe, efficient operations. End users must ensure that crane tolerances are within the specifications outlined by the Crane Manufacturers Association of America (CMAA). Key factors to monitor include elevation levels, spans, straightness, and runway clearances. Why Is Proper Runway Alignment Imperative? Aligned runways help…

Read MoreChoosing the Right Casters: How Much Force Is Required to Move the System?

For effortless movement of your gantry system, using the correct casters is key. At Spanco, we commonly quote three types of swivel casters: polyurethane, nylacron, and pneumatic. Each type of caster comes with its own pros and cons. How do you know which one is best for your system? The materials that each caster is…

Read MoreWhat Can Aluminum Do For You?

Aluminum: What’s So Great About it? There are many reasons aluminum works so well for construction, manufacturing, and HVAC applications: flexibility and durability. But, what makes it lightweight enough that one worker can disassemble and transport an entire aluminum gantry crane, and yet strong enough for that same gantry to lift up to three tons?…

Read MoreOverhead Cranes for Limited Space and Low Headroom Applications

Whether your facility lacks overhead space or there are multiple overhead obstructions to contend with, installing an overhead crane can be cumbersome. However, there are economic solutions for applications requiring overhead lifting in a facility where headroom is limited. Under-running bridge cranes are ideal for applications requiring overhead lifts in a factory with low headroom…

Read MoreHow to Choose a Crane to Enhance Your Operations

When purchasing a quality crane for your manufacturing facility or operation, it’s important to consider not just the price of the equipment but also its capabilities and capacities. There are plenty of overhead cranes available in a fair price range, but the cost alone cannot dictate your decision when choosing the right crane for your…

Read MoreAdvantages of Tripod Cranes

Tripod cranes are flexible tools for lifting items in multiple industries, including film, furniture, military, waste management, and construction. They’re lightweight, highly portable cranes that can travel and stand where other lifting equipment can’t. Learn more about tripod crane benefits and how they compare to other cranes in this guide. Understanding Tripod Cranes Tripod cranes are a type of lifting…

Read MoreHow Does Crane Deflection Impact Your Bottom Line?

How Does Crane Deflection Impact Your Bottom Line? Crane boom deflection refers to the vertical or horizontal displacement of parts of an overhead crane. Deflections affect the equipment’s performance by reducing its capacity and your employees’ productivity. Measuring your equipment’s deflection will help you understand the overall impact on your bottom line. How to Measure…

Read MoreManufacturing Facility Layout Plan

A manufacturing facility’s layout determines many aspects of production. By optimizing the arrangement of equipment, workers, and materials, you can make the most of your available space. An effective facility layout can help improve productivity, reduce downtime, ensure employee safety, and streamline workflows and operations. Since the layout of manufacturing facilities can vary widely, creating…

Read More