Workstation Bridge Cranes

ERGONOMIC OVERHEAD CRANE SYSTEMS BUILT TO LAST

We have thousands of pre-engineered overhead cranes, all of which can be fully customized to meet the needs of your specific application. Our certified engineers enjoy the challenge of creating custom systems for unique applications. All Spanco cranes come with the best warranties in the industry.

Spanco offers various pre-engineered and custom overhead bridge cranes that meet the material handling needs of different industries. Our certified engineers are experts at problem-solving and will create innovative custom crane systems for even the most complicated applications.

The Role of an Overhead Bridge Crane

An overhead bridge track crane system is an ergonomic crane that helps workers move materials on a hoist or similar attachment from one location to another more safely. Workstation lifting devices cover a rectangular area since the crane can move forward, backward, and side to side. Workers can move loads more productively with an overhead traveling crane than with other material handling systems since they require less manual effort.

The crane will move the load more safely, preventing damage to the product. Heightened productivity after implementing the overhead bridge cranes can result in higher profits for your company. Your investment will soon pay for itself.

Features and Benefits of Spanco Workstation Crane Track System

Our workstation lifting systems effectively move heavy loads to reduce manual labor requirements. Advantages of Spanco bridge cranes include:

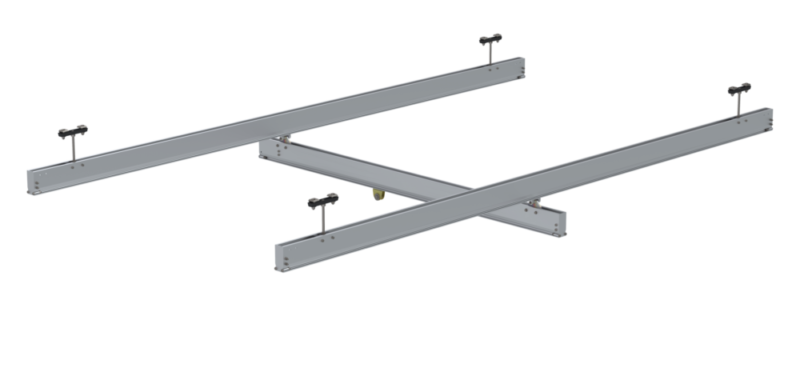

- User-friendly: They use an enclosed, rigid track that is easy to operate and control.

- More ceiling space: Our track’s low profile makes optimal use of the ceiling space.

- Smooth operation: The track features a V-shape profile to prevent dirt accumulation and maintain end truck and trolley wheel alignment for smooth movements.

- Long-lasting: Polyamide wheels are wear- and chemical-resistant and can support high load-bearing capacity for a long operating life.

- Ability to relocate: If your facility is rented or your workflow changes, you can easily move your overhead bridge to fit the new layout.

Other features of our overhead bridge cranes include end-stop bumpers to increase impact resistance, tractor drives for heavier or repetitive loads, and motorized bridge and trolley travel.

Our Workstation Bridge Cranes for Sale

A Spanco Workstation Bridge Crane can move loads of up to 4,000 pounds. We have both ceiling-mounted and freestanding traveling crane options. To decide which workstation bridge crane will suit your facility, consider the support structures, available space, mobility needs, and expansion opportunities:

- Ceiling-mounted workstation bridge cranes: Our ceiling-mounted workstation bridge cranes have bridge lengths of up to 40 feet and virtually unlimited runway length. They are ideal for areas with limited floor space or large mobile equipment. These configurations allow for the expansion of runways, bridges, and monorail crane systems as your operations expand.

- Freestanding workstation bridge cranes: Our freestanding workstation cranes feature bridge lengths up to 40 feet, virtually unlimited runway lengths, and trolley-hook heights up to 20 feet. The freestanding workstation crane is installed on a column for places with ceiling obstructions or lack a secure overhead structure. These cranes allow for relocation and business expansion. The freestanding systems have telescoping bridges to put parts into a machine or another workstation or reach beyond and under obstacles. Between the two bridges are runway tracks with bridge buffers to prevent the bridges from going over the crane’s capacity.

Bridge Crane Applications

Since overhead bridges are ergonomic and have high lifting capacities, they support numerous activities in manufacturing and transporting materials. Some industrial sites that benefit from overhead traveling cranes include:

- Warehouses and manufacturing facilities

- Steel fabrication

- Automotive manufacturing

- Paper mills

- Agriculture

- Power generation

- Aviation and railroad industries.

Handle Materials and Production Workstations With Ease

At Spanco, we manufacture our cranes to meet industry guidelines and standards, including those of OSHA and ANSI. We’re certified to ISO 9001:2015 for quality assurance with our customers, distributors, and representatives. All of our welders are certified by the AWS, and our bi-coastal manufacturing facilities have the Certified Welding Fabricator (CWF) designation. Our excellent material handling systems are covered by the industry’s most comprehensive warranties — two years for finishes, paint, and equipment and 10 years for manual equipment and systems.

For more than 30 years, we have provided effective material handling solutions for maintenance, machining, manufacturing, and more. View all categories of our workstation cranes and use the system selector to narrow the results by system type, mounting method, movement, and other factors. For more information, find a dealer near you or contact us online today.

Spanco Workstation Bridge Crane Resources

- Workstation Cranes Warranty Information

- Workstation Bridge Cranes Product Brochure

- Spanco Bridge Crane Case Studies

- Workstation Cranes Photo and Video Gallery

New Standards Available:

Spanco, a proud MMA member of MHI’s Overhead Alliance, announces updated ANSI standards for Enclosed and Patented Track Underhung Cranes and Monorail Systems. The new standards are available for purchase on the MHI/MMA website today.

Link to new standards: https://www.mhi.org/mma#Standard

ANSI MH27.2-2025, Enclosed Track Underhung Cranes and Monorail Systems– https://my.mhi.org/s/store#/store/browse/detail/a153h000005lJuY

ANSI MH27.1-2025, Patented Track Underhung Cranes and Monorail Systems — https://my.mhi.org/s/store#/store/browse/detail/a153h000005lJuX